FEATURES

- High operating rotating speed, large axial-load cutting drilling system were designed,which based on the working requirement related to soft rock. Matching medium or low pressure compressor to achieve drilling demand which need to be faster and more economic.

- It has a high drilling frame structure and four-point hydraulic expansion leg suitable for large-scale mining,which has excellent ground adaptability.

1.Cab of full hydraulic surface down-the-hole drilling rig

The cab provides safe operation environment for operators,intensive design of electronic buttons and hydraulic handles with reasonable layout.

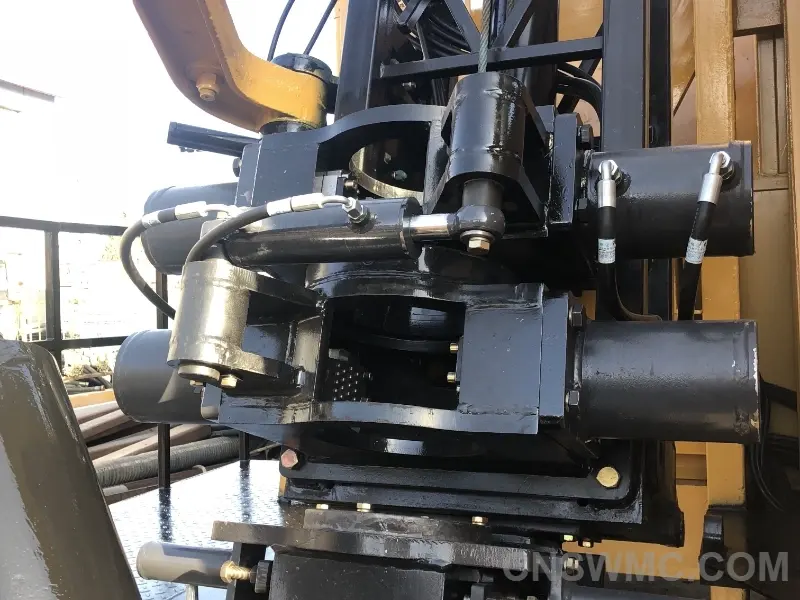

2.Automatic rod change device of full hydraulic surface down-the-hole drilling rig

The automatic drill rod library is equipped with bionic manipulator and rotary drill rod storage. An operator can complete the work of changing rods and drilling holes, reducing the difficulty of

operation, saving labor, to achieve the high efficiency and reliability performance.

3.Dust removal system of full hydraulic surface down-the-hole drilling rig

Two-stage dry dust removal system or high-pressure water dust removal system can effectively reduce dust and maintain a clean working environment.

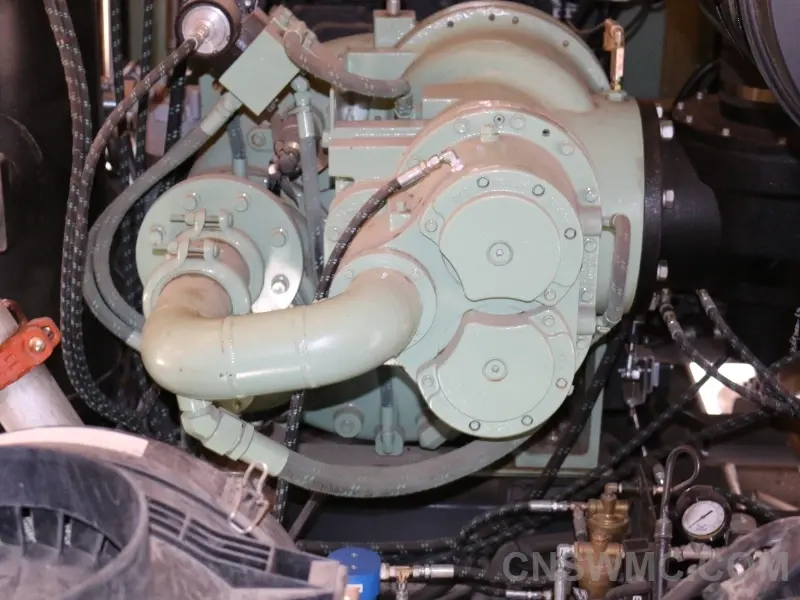

4.Two-stage screw compressor of full hydraulic surface down-the-hole drilling rig

Can be equipped with a variety of international brands(Sullair, Airman, Sullivan Palatek, Doosan, Gardner Denver...)of two-screw compression host, to ensure a higher impact frequency, and a good slag effect.

Specifications:

| Technical Parameter | SWDM 255A |

| Drilling hole diameter | 178-255mm |

| Drill rods | 133*8900/133*9000mm |

| Maximum hole depth | 18000mm |

| Compressor power | 354Kw/1850Rpm |

| Compressor pressure | 2.4Mpa |

| displacement | 31.2m³/min |

| Drill Car Engine Power | 132Kw/2200Rpm |

| Turning speed | 0-80Rpm |

| Turning torque | 6190N.m |

| Lifting force | 60KN |

| Dimensions | 13900*2950*3500mm |

| Weight | 30000kgs |

| Dust removal system | Two dust removal schemes(Dry or Wet)for users to selection |