FEATURES:

1.Rotary reducer

The internal structure is reasonable and easy to maintain. The rotary head is replaced with an enhanced shock absorber, which can reduce the impact reaction force of the drilling. The gear-type rotary motor has fast speed, large starting torque, rapid start and stop, and reliable. It has overload protection and low temperature rise for long-term work.

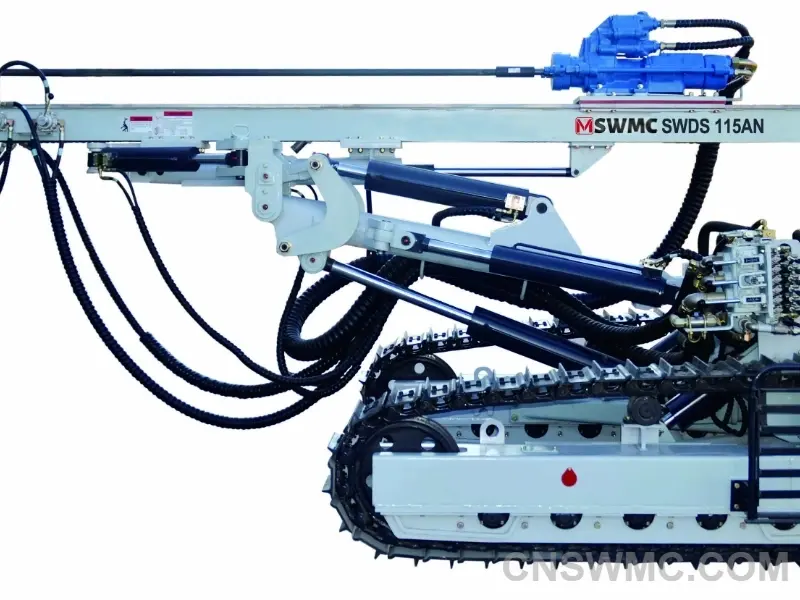

2. Strong chassis

The high-strength running mechanism provides strength and durability for the whole machine. The surfaces of the drive wheels, guide wheels, track rollers, and track pads are all specially wear-resistant. The drive is strong and the adaptability is good, enabling the equipment to be used in complex terrain Maintain a stable walking posture. Use one-time oil lubrication to avoid the tedious of frequent maintenance and maintenance during use.

3. Central control hydraulic system

The ergonomically designed integrated control console integrates hydraulic actuators, drilling systems, etc. in one place to optimize operability and operating efficiency. The body is equipped with a foldable detachable operation pedal to meet the requirements of single-person operation.

4. Robotic arm

The new structure of the mechanical arm mechanism expands the drilling direction and working range through five coupling mechanisms and hydraulic oil cylinders. Extended carriage, manganese steel slide rail and multi-group roller design skateboard can withstand large torque, resist deformation, and extend the service life of the carriage.

MAIN SPECIFICATIONS

| Drilling hole diameter | 90-165mm |

| Max actual air pressure | 2.5Mpa |

| Air consumption | 1.73/0.3Mpa m³/min |

| Turning torque | 2000N.m |

| Turning speed | 70Rpm |

| Pushing lenght | 3980mm |

| Maximum pushing force | 11KN |

| Sliding frame swing | Left 47°/Right 54° |

| Drilling boom swing | Left 40°/Right 40° |

| Drilling boom pitching | horizontal 23°/46° |

| Grade ability | 35° |

| Feeding motor power | 3.8Kw |

| Dimension | 6100*2360*2105mm |

| Weight | 5400kg |